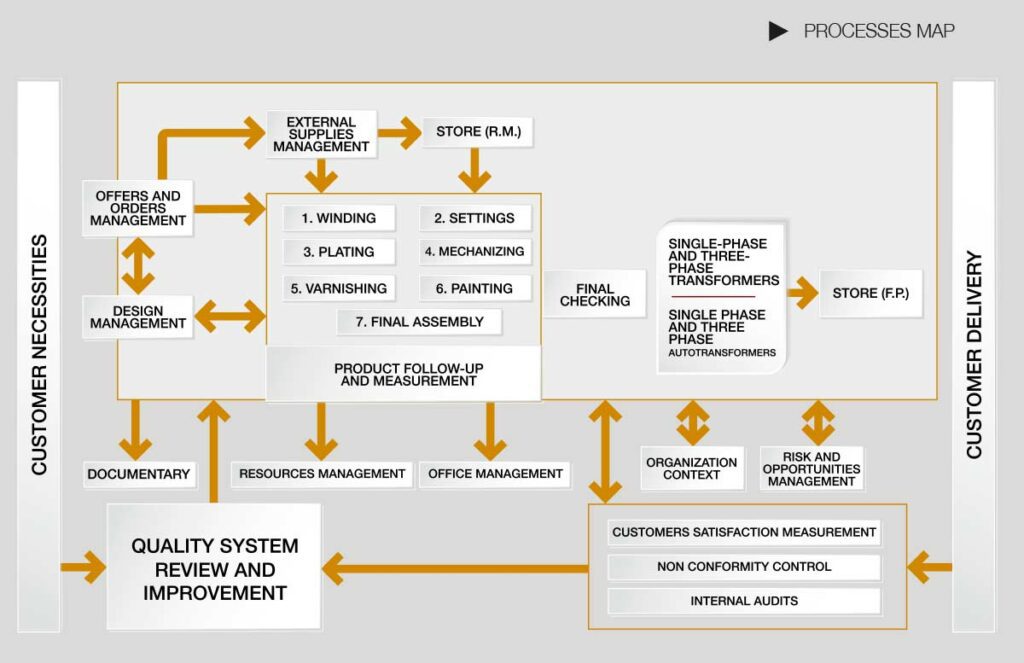

PROCESS DESCRIPTION

A process is an activity or a set of activities that uses resources and is managed to transform the incoming elements into results.

To ensure the efficient operation of the organization, numerous processes and interactions among them have to be identified and managed. The efficacy of such processes and interactions shall be measured using a range of required indicators in the stipulated documented information.

Processes and interactions of MANUMAG S.L. are identified in the PROCESS MAP that, in turn, uses the Plan-Do-Check-Act procedure as its point of reference. It also addresses the risks and opportunities defined above.

OFFER AND ORDER MANAGEMENT PROCESS

CIt is the initial stage of MANUMAG SL activity which implies:

- The requirements specified by the customer that include the requirements for delivery activities and the ones that follow.

- The requirements not set by the customer but necessary for specified or intended purposes when known.

- The legal requirements and regulations applicable to the product.

- Any additional requirement that MANUMAG S.L. deems necessary.

MANUMAG S.L. sets the appropriate contract/order with a client upon examination of the product-related requirements.

The methods set up for this process are documented in the procedure PG-Q-01 “Offer and Order Management Process”.

Design Process shall be directly interrelated with this process in the event of ordering the transformers with individual requirements (special transformers,….).

DESIGN PROCESS

MANUMAG S.L. shall develop new transformers and autotransformers, as well as modify the existing ones based on customer requirements.

To set up the action method for this event, the procedure PG-Q-01 “Design Management Process” has been documented.

CONTROL PROCESS OF EXTERNALLY SUPPLIED PROCESSES, PRODUCTS, AND SERVICES

This process includes all activities carried out to ensure the compliance of the externally supplied processes, products and services. It is deemed as a part of another starting phase of the activity meant mainly for item manufacturing.

Raw materials (wire, sheets, …) as well as auxiliary ones (packaging material, …) shall be purchased based on the requirements of the specific moment in time.

To specify all these, a procedure PG-Q-03 “Control Process of the externally supplied processes, products and services” is set up. In it, the organization makes sure that the externally supplied processes, products and services shall not have any adverse effect on its capacity to deliver conforming products to its customers applying the criteria to assess, select, track the performance and reassess the external suppliers regarding their ability to deliver processes, products and services in accordance with the specified requirements.

PRODUCTION PROCESS

This process includes all operations performed from production order planning /launch to the effective execution of the finished product.

This process also includes follow-up monitoring and measurement operations associated with the product in its various phases (except for the finished product, which is specified in the final verification detailed herein).

The procedure PG-Q-04 “Production Management Process” and Technical Supplementary Procedures are documented to help perform this process properly.

FINAL INSPECTION PROCESS

All 100% of the devices manufactured by MANUMAG S.L. must get the final inspection since it is the only way to demonstrate their conformity to the acceptance criteria stipulated for such products before they are sent to the customers.

The action method for this event is specified in the procedure PG-Q-05 “Final Inspection Management Process”.

STORAGE PROCESS

MANUMAG S.L. has two warehouses: one for raw materials and the other one for the finished product.

These warehouses directly interrelate with the global process (warehouse for raw materials with the control processes of the externally supplied processes, products and services and production and the warehouse for finished product with the final verification process). The operations to be performed in the warehouse are specified in the procedure PG-Q-06 “Storage Management Process”.

CONTEXT DETERMINATION OF THE ORGANIZATION PROCESS

The procedure PG-Q-15 “Context of the Organization Management Process” has been developed to determine and specify both external and internal issues that can affect the ability of the organization to get the previously established results by the strategic management planning, as well as to see the needs and expectations of the interested parties.

RISK AND OPPORTUNITY DETECTION PROCESS

Given that the key planning factor of the organization Quality Management System is to consider risks and opportunities that may affect MANUMAG S.L., the procedure PG-Q-16 “Risk and Opportunity Management Process” shall be implemented.

FOLLOW-UP MONITORIG AND MEASURING PROCESS

This process uses different tools to compile the necessary information so as, on the one hand, to perform a systematized management of the follow-up monitoring and occasional measuring of different processes and, on the other hand, to be the input data source for the “Inspection and Improvement of the Quality System” process.

The processes developed to set up the methods required are PG-Q-11 “Nonconforming Output Control Process”, PG-Q-12 “Internal Audit Performance Process” and PG-Q-13 “Measuring Customer Satisfaction Process”.

DOCUMENTING PROCESS

In order to have proper control of the documented information in each of the existing processes at MANUMAG S.L., a Documenting Process shall be established. It shall specify the following levels of documentation:

- Quality Manual

- General Procedures

- Technical Procedures

- Records

The external documentation (legislation, regulations, ….) required for proper system operation has to be taken into consideration, too.

The description of the documenting process implies making procedures PG-Q-07 “Documentation Control Process” and PG-Q-08 ”Records Control Process”.

RESOURCE MANAGEMENT PROCESS

Requirements for the resources are specified based on the execution and analysis of different processes. The resources in question might be human (related with competence, awareness, working environment and communication with the staff) or material (related with the infrastructure maintenance, calibration of measurement equipment, …) ones.

The specification of this process includes the documented procedure PG-Q-14 “Resource Management Process” and Technical Procedures for calibration.

ADMINISTRATIVE MANAGEMENT PROCESS

Documented information is set as a part of the processes that complement the quality management system. It shall include the steps to follow when performing the tasks of the Administration Department and those outlined in the customer and supplier/creditor accounting. For it the procedure PG-Q-17 “Administrative Management Process” shall be generated.

PERFORMANCE ASSESSMENT AND IMPROVEMENT OF THE QUALITY MANAGEMENT SYSTEM PROCESS

After having planned and established the processes that make up the Quality System, the Senior Management of MANUMAG S.L. proceeds to inspect these within the stipulated intervals, making sure it preserves its continuous convenience, adequacy, efficiency and alignment with the strategic management of the organization. The input information to be used for such inspection shall include changes regarding the external or internal issues that affect the Quality Management System, information about performance and efficiency of the Quality Management System, status of the previous inspection actions carried out by the management, adaptation of the recourses, efficacy of the actions performed to tackle the risks and opportunities, as well as the opportunities for improvement.

Opportunities for improvement, resource needs or any need for change within the Quality Management System shall be deemed as an output of the process.

For a better definition of this process, the procedures PG-Q-09 “Senior Staff Leadership Management Process” and PG-Q-10 “Improvement Actions Management Process” have been documented.